At Plastic Supplies Dudley, we understand that material choice makes or breaks a product’s performance. That’s why we offer a wide selection of carefully sourced plastic injection moulding materials – each engineered to deliver exceptional results across industries.

We’ve built our reputation as one of the leading UK plastic injection moulders by prioritising quality at every stage. From automotive refinishing to consumer electronics, our materials power reliable, durable, and cost-effective products.

Let’s walk you through our most trusted material options – and how to choose the best one for your manufacturing needs.

Why Material Choice Matters in Injection Moulding

Material selection isn’t just a technical decision – it’s a strategic one. The right plastic defines:

- Component strength and flexibility.

- Chemical and temperature resistance.

- Environmental sustainability.

- Cost and manufacturing efficiency.

At PSD, we consult with you from the start to determine the best-fit material for your application. Whether you’re building lightweight housings or impact-resistant parts, we match the ideal polymer to your end goal.

Our Most Popular Plastic Injection Moulding Materials

We stock and source a diverse catalogue of polymers, but here are the most commonly requested materials – each offering distinct advantages.

1. Polypropylene (PP)

Lightweight, cost-effective, and chemically resistant, Polypropylene is ideal for:

- Automotive components (e.g. bumpers, wheel covers).

- Packaging (e.g. strapping tape, flat bags).

- Medical trays and containers.

PP delivers excellent flexibility and fatigue resistance, making it a popular choice for high-volume, disposable, or semi-structural parts.

2. Nylon (PA6, PA66, PA12)

Nylon offers high tensile strength, chemical resilience, and thermal stability. It’s widely used in:

- Under-the-hood automotive components.

- Electrical connectors.

- Mechanical gears and bushings.

Its moisture-absorbing properties also enhance flexibility, making it a go-to for durable and load-bearing parts.

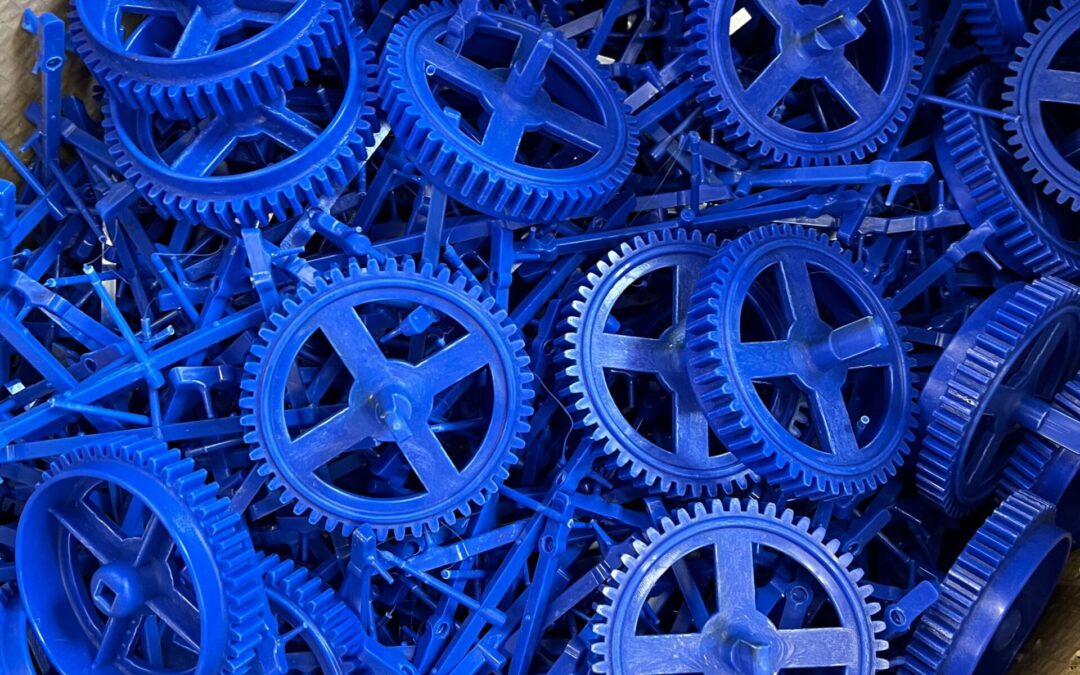

3. Acetal (POM)

Known for dimensional stability and low friction, Acetal is a performance engineering plastic used in:

- Industrial gears and bearings.

- Medical device components.

- Consumer electronics with moving parts.

Its ability to retain shape under pressure makes it ideal for precision mechanical parts.

4. ABS (Acrylonitrile Butadiene Styrene)

ABS is durable, easy to process, and impact-resistant – making it a favourite for:

- Consumer electronics.

- Automotive interior parts.

- 3D printing and prototyping.

Its low melting point allows for rapid production and recyclability, supporting sustainable workflows.

Why Choose PSD for Your Plastic Injection Moulding?

Plastic Supplies Dudley isn’t just a supplier – we’re a strategic manufacturing partner. Our team works alongside yours to identify the right material, tool design, and processing parameters to maximise your product’s performance.

We combine:

- Decades of plastics experience.

- In-house toolmaking and material testing.

- Fast turnaround and competitive pricing.

- Consistent quality assurance.

By partnering with us, you can reduce delays, cut costs, and ensure long-term product success.

Industry Applications of Our Injection Moulding Materials

Our materials are engineered to meet exacting standards across diverse sectors:

- Automotive: Underbody and interior components.

- Consumer goods: Appliances, kitchenware, and packaging.

- Industrial: Tooling, machine housings, and fasteners.

- Medical: Sterile containers, housings, and delivery systems.

Need a custom formulation?

We source high-performance blends tailored to temperature resistance, flame retardance, conductivity, and more.

Sustainability at the Core

PSD prioritises environmental responsibility by offering:

- Recyclable and biodegradable plastics.

- Regrind and post-consumer material options.

- Closed-loop production to reduce waste.

- Energy-efficient machinery.

We’ll help you meet your sustainability goals without compromising on performance or regulatory compliance.

FAQs

1. What’s the best material for automotive plastic components?

Polypropylene (PP) and Nylon (PA) are popular in automotive injection moulding due to their chemical resistance, flexibility, and temperature tolerance. We offer both, with custom grades available for specific performance targets.

2. Can you help me choose the right injection moulding material?

Absolutely. Our technical team will assess your product function, stress loads, and environmental exposure, then recommend the most suitable material for optimum performance.

3. Do you supply custom plastic injection materials in the UK?

Yes. As UK-based plastic injection moulders, we offer off-the-shelf and custom-blended materials based on your industry, compliance, and durability needs.

4. Are your plastic moulded components suitable for food or medical use?

Yes. We supply FDA- and ISO-compliant materials for use in sterile, food-grade, and medical device environments. Certificates of conformity are available upon request.

5. How quickly can you deliver plastic moulded parts using these materials?

Turnaround depends on complexity, but we’re known for fast lead times. Most standard projects move from tooling to delivery in under 3 – 4 weeks.

Partner with a Trusted Plastic Injection Moulding Expert

At Plastic Supplies Dudley, we combine expert knowledge, premium materials, and a customer-first approach to deliver plastic moulded components that last.

Whether you’re scaling production or launching a new design, we’re here to support your next step.

Contact our team For tailored material recommendations and a fast, competitive quote.

Email: info@plasticsuppliesdudley.co.uk

Tel: +44 (0) 1384 77569

Tel: +44 (0) 1384 486660