At Plastic Supplies Dudley, we specialise in the development and production of high-quality components for businesses across the UK. With decades of experience in plastic component manufacturing, we’ve seen the industry transform – particularly in the last ten years.

In this blog, we explore how innovative technologies are driving new possibilities in design, sustainability, automation, and more. If you’re looking to future – proof your production or understand how advanced manufacturing works today, this guide is for you.

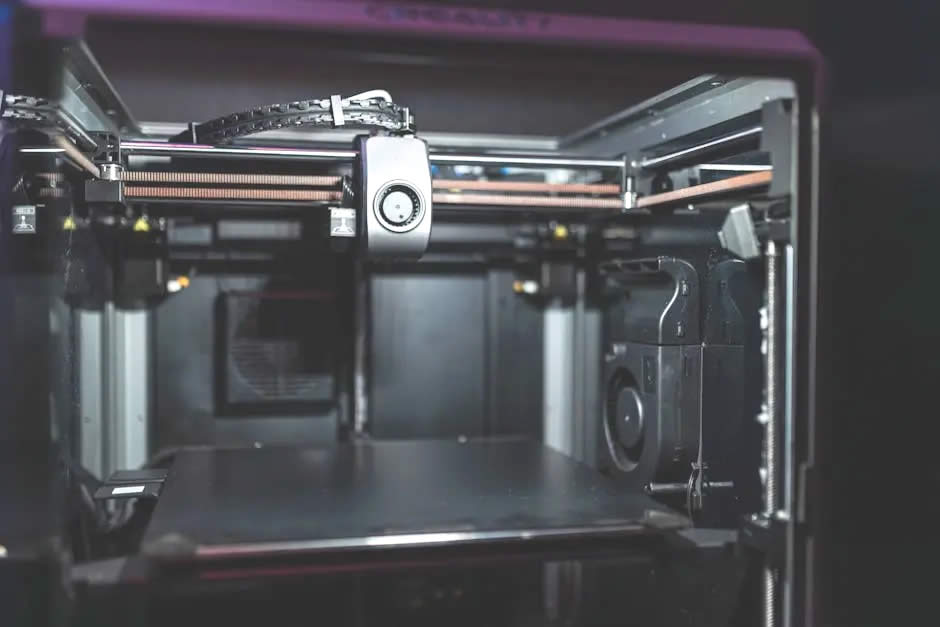

3D Printing: A Revolution in Rapid Production

3D printing is now a vital part of modern plastic manufacturing. Also known as additive manufacturing, it builds parts layer by layer – making complex designs easier and faster to produce.

Benefits include:

- Rapid prototyping: Turn ideas into testable parts in hours.

- Lower waste: Only the material needed is used.

- Customisation: Create bespoke components on demand.

Industries such as aerospace, healthcare, and automotive are already adopting 3D printing to reduce costs and speed up development. At PSD, we use these techniques to help clients quickly test new concepts before committing to full production.

There are challenges – material selection and equipment investment – but the future looks promising. With new printable polymers being developed regularly, the scope is expanding.

Sustainable Materials Changing the Landscape

Sustainable plastic manufacturing is no longer optional. It’s expected.

We’re seeing growing adoption of:

- Bioplastics made from corn or sugarcane.

- Recycled materials incorporated into new parts.

- Biodegradable plastics for single-use applications.

These materials reduce reliance on fossil fuels and lower carbon emissions. At Plastic Supplies Dudley, we’ve helped clients switch to eco-friendlier compounds without sacrificing strength or finish.

However, it’s not all smooth sailing. Costs can be higher, and biodegradability can vary depending on conditions. That’s why expert guidance is crucial when selecting materials for your application.

Choosing sustainable options improves brand reputation and meets rising consumer demand for ethical products – giving you a marketing edge as well.

Automation: Boosting Efficiency and Precision

Automation in plastic production helps manufacturers meet tight deadlines with fewer errors. It’s about making processes smarter, not just faster.

Key benefits include:

- Consistent output.

- Reduced human error.

- Lower long-term labour costs.

- Increased safety.

At PSD, we’ve integrated automation into our production lines – from material handling to part finishing. This allows us to deliver on time, every time, while ensuring consistent quality.

Some fear that automation will reduce jobs, but we see a shift instead. Today’s workers are learning to manage robotics and software – adding value in new ways. Training and upskilling are essential to future-proof the workforce.

Design Innovation: From Concept to Creation

Thanks to advanced design tools like CAD and simulation software, plastic component manufacturing has never been more creative.

This means:

- Faster development cycles.

- Reduced prototyping costs.

- More visually appealing and functional products.

Design teams can visualise parts, simulate real-world performance, and fine-tune everything before the mould is cut. This leads to more reliable components and less waste.

Design also drives market differentiation. Sleek, efficient, and user-friendly parts are now the expectation – especially in consumer electronics and medical devices. With strong collaboration between design, engineering, and marketing teams, standout products are easier to achieve.

IoT Integration in Plastic Manufacturing

The Internet of Things (IoT) is reshaping how we monitor, manage, and improve manufacturing processes.

In a plastic factory, IoT devices can:

- Monitor machine performance in real-time.

- Flag maintenance needs before breakdowns occur.

- Track material usage.

- Ensure production stays within quality thresholds.

This live data reduces downtime, enhances traceability, and empowers better decision-making. At PSD, we’re actively exploring IoT integration to further streamline operations and support client requirements for traceability and compliance.

Looking ahead, smart factories will become the norm. IoT is central to that vision, allowing companies to scale production without losing control.

FAQs

What industries benefit most from advanced plastic component manufacturing?

Automotive, healthcare, aerospace, electronics, and packaging all benefit from innovations like 3D printing, automation, and sustainable materials.

Is sustainable plastic strong enough for industrial use?

Yes, many bio-based and recycled plastics now match traditional polymers in strength, flexibility, and durability – especially with proper design.

How does automation affect quality control?

It improves it. Automated systems reduce human error and monitor output in real time, ensuring consistency and precision.

Can 3D-printed plastic parts be used in production, not just prototyping?

Absolutely. With the right materials, 3D printing is now used for end-use parts – especially in low-volume, high-customisation scenarios.

The Future Starts with Innovation

Innovations in plastic component manufacturing are driving the industry forward. From sustainable materials and automated systems to intelligent design and connected factories, the landscape is evolving quickly.

At Plastic Supplies Dudley, we stay at the forefront of these changes. Whether you need mass-produced components or low-volume, high-precision moulding, we provide future-ready solutions tailored to your needs.

Investing in innovation today ensures you remain competitive tomorrow. We’re here to help you lead.

Email: info@plasticsuppliesdudley.co.uk

Tel: +44 (0) 1384 77569

Tel: +44 (0) 1384 486660