At Plastic Supplies Dudley, we bring over 50 years of experience to every plastic product we manufacture. As specialists in custom injection moulding UK, our insight into the evolving applications of custom plastic moulds puts us at the forefront of innovation. This blog explores how these tools are driving transformation across industries and why they are integral to future-ready manufacturing.

What Are Custom Plastic Moulds?

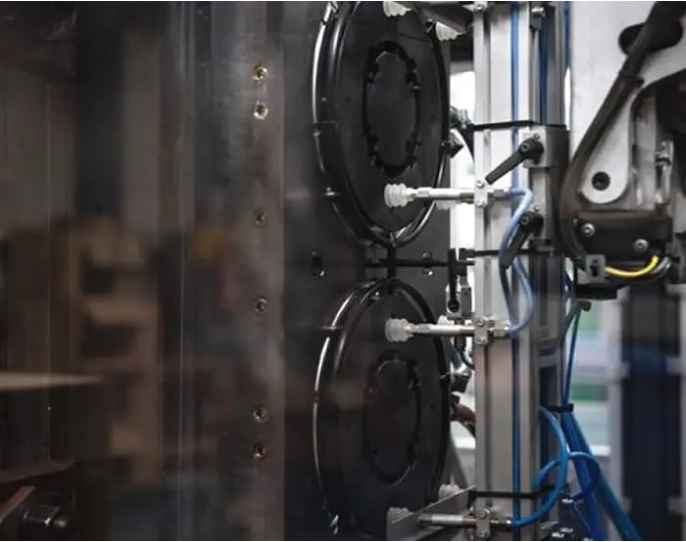

Custom plastic moulds are specially designed tools that shape plastic into a desired product. Unlike off-the-shelf moulds, custom solutions are engineered to fit unique specifications, ensuring precise results.

The process begins with design, usually aided by CAD (Computer-Aided Design). It then progresses through CNC machining, fabrication, and testing phases. This guarantees each mould meets exact tolerance and material demands. At PSD, we specialise in plastic mould tooling that supports both small and large batch production across a wide range of industries.

Driving Product Innovation with Prototyping

Custom plastic moulds are vital during the prototyping phase. They help manufacturers test product concepts quickly without committing to mass production.

Fast feedback loops: Test and refine products before scaling.

Cross-team input: Engineers, marketers, and designers can all influence the outcome.

Accurate simulation: Prototype products reflect the final version, enabling realistic testing.

By embracing custom moulds early in the product development cycle, businesses speed up time to market and reduce financial risks.

Supporting Sustainable Manufacturing

One of the most exciting developments in custom moulding solutions is their role in eco-friendly production. Custom moulds allow manufacturers to reduce waste and utilise sustainable materials.

Here’s how:

Material optimisation: Reduce plastic waste by tailoring moulds to use minimal material.

Recycled and biodegradable options: Many of our moulds are compatible with recycled plastics and bio-based resins

Extended tool life: High-quality tooling lasts longer, reducing the need for replacements.

Customers today expect sustainability. Our precision processes and tooling make it easier for clients to meet environmental targets without compromising quality.

Applications Across Diverse Industries

The adaptability of custom plastic moulds means they are in demand across multiple sectors. Let’s explore where they shine:

Automotive

We’ve worked with leading names like Jaguar Land Rover and Aston Martin, delivering custom-moulded components like dashboards, centre consoles, and light fixtures

Healthcare

From IV bags to surgical tool casings, the healthcare sector depends on precise, sterile, and safe plastic parts. Custom moulding ensures strict compliance with medical-grade standards.

Consumer Goods

From kitchen gadgets to homeware, fast-moving consumer goods benefit from quick-turnaround prototyping and scalable production enabled by custom injection moulding.

Marine and Composite Sectors

Wedges and mould-release tools we manufacture are tailored for GRP (glass-reinforced plastic) production, used in marine and industrial applications.

Technology-Driven Flexibility

At PSD, our commitment to innovation is built into our process. Our use of modern machinery, CAD software, and CNC equipment allows us to:

- Create precision moulded plastic parts

- Deliver short lead times

- Support low and high-volume orders

We also support insert moulding and overmoulding for complex multi-material components.

Future of Custom Moulding: Smart, Adaptive, and Agile

Emerging technologies such as AI-powered design tools and 3D printing are reshaping the future of custom moulding. Soon, businesses will be able to iterate products on demand and dynamically adapt tooling with near-zero delay.

Material science is also advancing. New polymers offer enhanced heat resistance, flexibility, or biodegradability—broadening what’s possible with plastic moulding.

Why Choose Plastic Supplies Dudley?

We’re not just a supplier—we’re your strategic partner in manufacturing. Here’s what sets us apart:

- 50+ years’ experience and ISO certifications

- Family-run, with a passion for precision

- Flexible volumes and sustainable material use

- Competitive tooling costs and collaborative support

Whether you need a new prototype, an eco-conscious part, or a full-scale production solution, Plastic Supplies Dudley is ready to help you.

FAQs

What materials can be used in custom plastic moulds?

We support a wide range of thermoplastics, including polypropylene, ABS, nylon, acetal, polycarbonate, and recycled plastics.

Can I use custom plastic moulds for low-volume runs?

Yes. We provide flexible solutions for both prototype and full-scale production, including low volume injection moulding.

How long does it take to make a custom plastic mould?

Timelines vary depending on complexity but typically range from a few days for simple tools to several weeks for more complex items.

Do you offer design support?

Absolutely. We collaborate with your team to ensure the mould aligns with your design and functionality goals.

Conclusion: Unlocking the Future with Custom Plastic Moulds

The future of plastic manufacturing lies in innovation—and custom plastic moulds are key to unlocking it. Whether you’re reducing waste, enhancing product performance, or launching a new idea, these solutions give you the edge to succeed.

At Plastic Supplies Dudley, we bring deep expertise, state-of-the-art equipment, and a commitment to sustainability to every project.

Contact Us

Email: info@plasticsuppliesdudley.co.uk

Tel: +44 (0) 1384 77569

Tel: +44 (0) 1384 486660