The majority of the new enquiries we get coming into Plastic Supplies Dudley are from individuals or companies that have no background knowledge on plastics materials or injection moulding. This is why it is essential to get in touch with a injection moulding company like ours at the design stage of your new product.

For instance, one example we have recently had is from a heating and ventilation company. They were looking for a material with the highest fire resistance possible for their new product. This company was an existing customer of ours, but they had no experience in using fire resistant materials. So, they came to us right at the beginning of the design stage before a drawing had even been started.

Why is material selection so important for injection moulding?

Choosing the correct material from the beginning can protect you from expensive tooling adjustments in the future. It is less likely you will need to change the material further down the line.

Tool Design

Every tool will be designed around a specific material. Each material will have a different shrinkage rate which can range from 0.1%, all the way up to 6%. They will also need different gate sizes on the tool to allow the molten plastic to flow into the cavities with ease.

Environment

It is also important to know what environment your product is going to be used in.

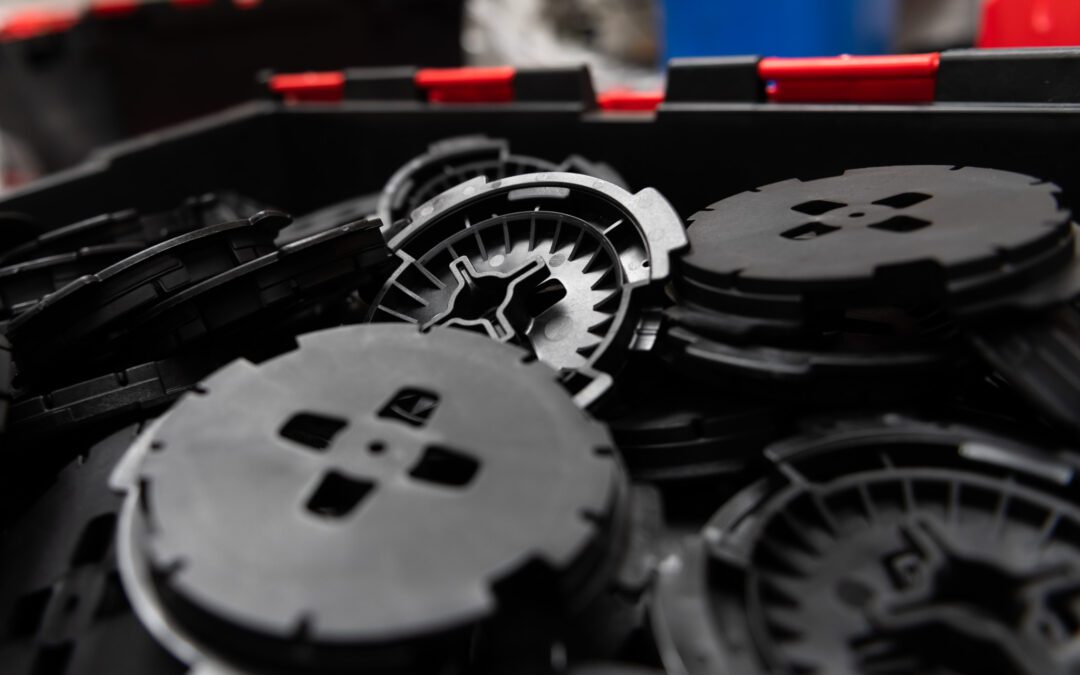

For example, one product that we make is a pedestal to support decking framework. As this is going to be taking a lot of weight with tables and chairs, as well as people walking over them. Therefore, we had to choose a material that was going to be able to withstand the weight, while also not degrading over time when left outside in the elements. We decided that a 30% glass filled nylon 6 would be ideal for this product.

What are the advantages to glass filled nylon 6?

This is due to its superior tensile strength and great stability when exposed to temperature fluctuations that can occur when outside.

What are the disadvantages to glass filled nylon 6?

There are some disadvantages to using this material such as greater wear on the tools. It can also have higher costs than a lot of other materials. But, we have got around that by using a reprocessed material. This uses recycled nylon 6 and puts fresh glass in to make sure the strength is not affected.

Related: Looking for an Injection Moulding Tooling Quote? Check Out These FAQs

What is the most popular injection moulding material?

The most popular materials we used here at Plastic Supplies Dudley are Polypropylene and Nylon. Most of our own products are moulded from Polypropylene. This is due to its good chemical resistance as well as being tough and having a good fatigue resistance.

For example, the main product we produce is a body filler spreader. These are used in many applications these days, but its main application is to apply body filler to cars when repairing a dent. The properties of polypropylene are perfect for this as it means the spreader will not affect the filler being applied to the car. In addition, it will also bounce back to its original shape once the filler has been applied.

Supply Chain Risks of Materials

We try to stay away from any materials that could be of risk to supply chain issues, but sometimes this is unavoidable. With many of the materials we use, we have multiple suppliers. So, we can generally always receive the materials within two days of ordering.

The more specialist the material, the worse it can be. There is one material we use which has the highest fire resistance you can get. As this is used very rarely, it can take up to 16 weeks to receive. Also it can have minimum order quantities of 1 tonne or more. This could obviously cause not only issues with lead times for your products, but also cash flow issues if you must purchase large amounts up front when you do not need that much.

Looking for an Injection Moulding Company?

With our exceptional capability to deliver superior moulding services to a range of industries and provide top-of-the-line automotive refinishing products, Plastic Supplies Dudley Ltd stands out from the rest. If you would like to know any more information on any materials or would like help in choosing a material for your new product then please get in touch with Plastic Supplies Dudley either via email at info@plasticsuppliesdudley.co.uk or by calling 01384 77569.