At Plastic Supplies Dudley, we’ve seen firsthand how advanced plastic moulding solutions transform manufacturing. In this blog, we’ll share our expertise to help you understand the wide-reaching benefits, especially for UK businesses seeking cost-effective, sustainable, and high-quality plastic production.

What Are Advanced Plastic Moulding Solutions?

Advanced plastic moulding refers to modern technologies used to create plastic parts efficiently and precisely. These include:

Injection moulding: Ideal for high-volume, high-accuracy components.

Blow moulding: Great for hollow items like bottles and containers.

Rotational moulding: Perfect for complex shapes with uniform wall thickness.

These solutions are essential across industries—automotive, medical, consumer goods, and beyond. They help reduce costs, improve quality, and speed up production.

Why Manufacturers Choose Modern Moulding Methods

Cost-Effective Production

Manufacturers often struggle to balance quality with cost. Advanced plastic moulding bridges this gap. By reducing material waste and energy use, you can lower production costs without sacrificing product performance.

- Less material waste equals direct cost savings.

- Energy-efficient machines cut operational expenses.

- High throughput allows quicker fulfilment of large orders.

At Plastic Supplies Dudley, our streamlined operations help clients save on every production cycle.

Design Flexibility for Complex Parts

Modern moulding techniques allow for creative, practical, and aesthetic product designs.

- Create intricate parts with fine details and smooth finishes.

- Tailor shapes to exact specifications with minimal tooling changes.

- Quickly iterate on prototypes before scaling to production.

Whether it’s an aerodynamic car part or a specialist cap or lid, we help bring your vision to life.

Enhanced Product Quality and Consistency

Consistency is key in manufacturing. With advanced plastic moulding:

- Products are formed with precise tolerances.

- High-speed moulding cycles ensure uniform output.

- Automated controls reduce human error.

Our team ensures every batch meets strict quality standards. That’s why our components are trusted across critical sectors like automotive and medical.

Sustainability in Plastic Moulding

Environmental responsibility is no longer optional. Advanced moulding supports sustainability in multiple ways.

Recycled and Eco-Friendly Materials

Using recycled plastics or bio-based polymers helps reduce environmental impact.

- Recycled LDPE and HDPE are used in many of our projects.

- Bioplastics are available for select applications.

Energy Efficiency

Newer machines consume less energy per part produced, lowering carbon emissions. At PSD, we continue investing in greener technologies to help clients meet their ESG goals.

Real-World Applications

Let’s explore how plastic moulding for manufacturers is used in real industries:

Automotive

We manufacture parts like bumper inserts, grille components, and cable housings that demand strength, precision, and resistance to heat and wear.

Construction

From durable plastic spacers to electrical boxes, moulded plastics help speed up installations and reduce labour.

Consumer Goods

Injection moulded lids, overcaps, and spreaders are produced for brands that value both quality and appearance.

Future Trends in Plastic Moulding

To stay competitive, manufacturers must embrace innovation. Here’s what’s shaping the future:

- Smart manufacturing: Real-time sensors and data analytics improve production visibility and reduce downtime.

- Advanced polymers: High-performance plastics are emerging with better heat resistance, strength, and recyclability.

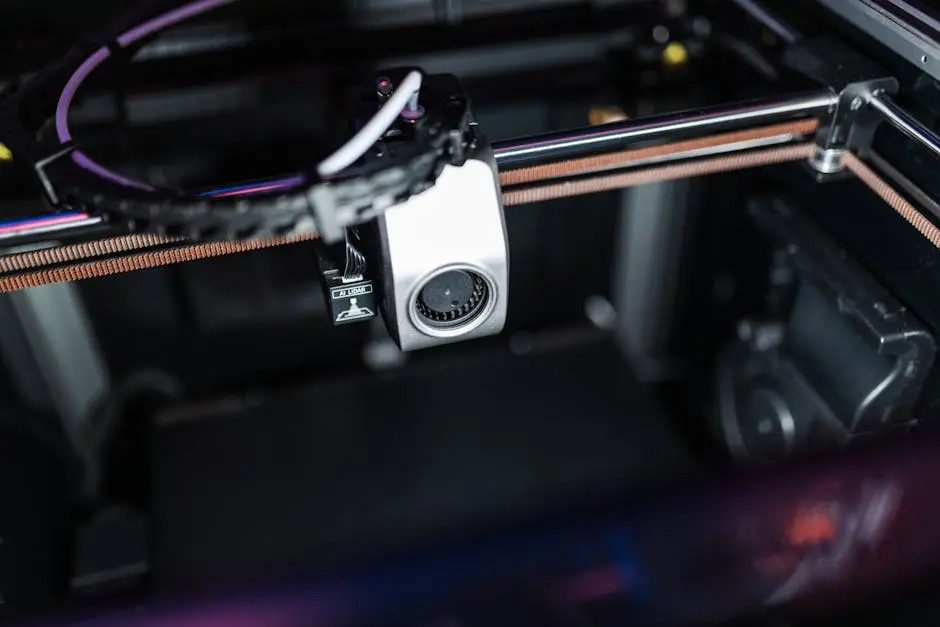

- On-demand tooling: 3D-printed tools shorten lead times and lower setup costs.

Plastic Supplies Dudley actively monitors and adopts these trends to help clients remain ahead of the curve.

Why Partner With Plastic Supplies Dudley?

We’re not just a plastic moulding company—we’re a trusted partner. Our team combines decades of experience with an appetite for innovation.

You get:

- End-to-end project support

- Precision UK-based manufacturing

- Eco-conscious production

- Competitive pricing and fast turnaround

We’re proud to serve industries across the UK with moulding solutions that perform.

FAQs

What are the main benefits of plastic injection moulding?

It offers high-speed, repeatable production with excellent consistency and material efficiency.

Can you mould using recycled plastics?

Yes. We often use recycled LDPE, HDPE, and other sustainable materials when suitable for the application.

How fast can you deliver moulded parts?

Lead times depend on project scope, but we offer fast turnaround, especially on repeat or pre-tooled projects.

Do you offer support with design and tooling?

Absolutely. Our in-house team provides full assistance, from CAD design through to tooling and testing.

Is advanced plastic moulding suitable for small batches?

Yes. While best for larger runs, we also support low-volume and prototype runs.

Conclusion: Choosing Smarter Moulding Solutions

From reducing costs to boosting sustainability and enhancing product quality, advanced plastic moulding is the future of efficient manufacturing. At Plastic Supplies Dudley, we bring together knowledge, capability, and customer care to deliver moulded parts that perform in every way.

Whether you’re launching a new product, improving an existing one, or exploring sustainable alternatives, we’re here to help.

Contact us today to find out how our plastic moulding services can support your next project.

Contact Details

Email: info@plasticsuppliesdudley.co.uk

Tel: +44 (0) 1384 77569

Tel: +44 (0) 1384 486660