High-Quality Overmoulding Services by PSD

50+ years' experience

UK Based Company

Family Business - 3 generations

ISO 9001 Accredited

Improving Product Design and Functionality with Overmoulding

At Plastic Supplies Dudley Ltd, we offer overmoulding services to improve the visual design and functionality of your products. Overmoulding allows for crucial details to be added to a product for consumer use.

At Plastic Supplies Dudley Ltd, we can handle parts up to 2.3 kilos. Simply submit your prototype or drawings, and we’ll work with you to find the ideal approach and provide a quote quickly.

After the go-ahead, we typically work with you on 2 or 3 trials to ensure that you get the quality you require. Let us help you take your product design to the next level with our professional and reliable overmoulding services.

Overmoulding Services from PSD

With over 50 years of experience, we are committed to providing high-quality overmoulding services that meet your unique requirements. Our experienced team will work closely with you throughout the overmoulding process to ensure that the final product meets your specifications. We use the latest technology and equipment to provide accurate and efficient overmoulding services.

With our overmoulding services, you can expect:

- Customised solutions tailored to your needs.

- Quality materials and advanced technologies for superior performance.

- Competitive pricing and quick turnaround times.

- Friendly and professional customer service.

Why Use Overmoulding?

Overmoulding is a process that can improve the functionality and appearance of a product. The process involves adding a layer of soft plastic (usually TPE) over a rigid plastic part.

Here are some of the key benefits of using overmoulding:

- Improved visual design and functionality – The process allows for crucial details to be added to your product for consumer use, making it more appealing and user-friendly.

- Extra grip and comfort for the user

- Adds flexibility to a rigid part

- Cuts out extra assembly time by eliminating the need for glue or other adhesives

- Providing a soft touch surface to a rigid product.

Overmoulding Applications

Overmoulding has a wide range of applications across various industries. Here are some of the industries that can benefit from our overmoulding services:

Automotive:

Overmoulding can be used to add soft-touch surfaces to dashboard components, shift knobs, and other automotive parts.

Medical:

Overmoulding can be used to create ergonomic medical devices that are more comfortable and easier to use.

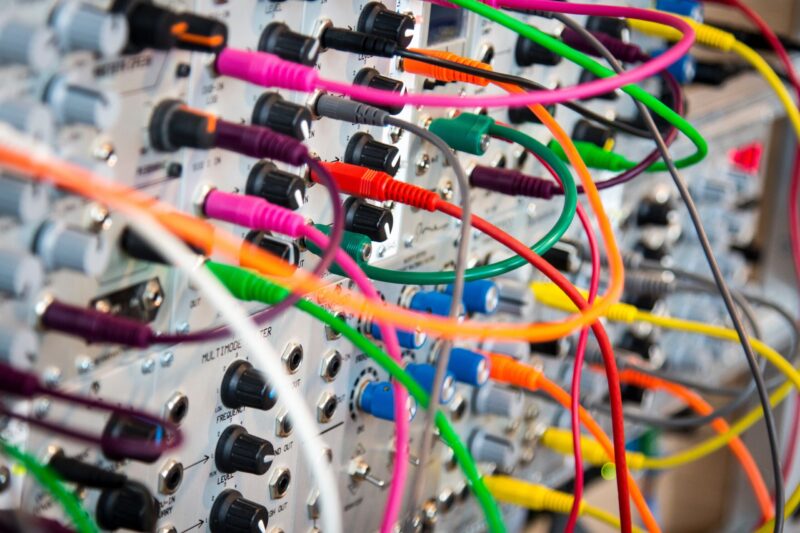

Electronic Devices:

Overmoulding can be used to add water-resistant or shock-resistant properties to electronic devices.

FAQs

What is overmoulding, and why is it important for product design?

What industries benefit from overmoulding services?

What are the benefits of overmoulding?

Why should I choose PSD for overmoulding services?

What materials are used in overmoulding?

How does overmoulding improve product functionality?

Can PSD handle complex designs in overmoulding?

How does overmoulding benefit automotive applications?

What is the typical process for overmoulding at PSD?

How can I get a quote for PSD’s overmoulding services?

PSD is committed to making your overmoulding project seamless and successful.

Choose Plastic Supplies Dudley Ltd for your overmoulding needs and experience the benefits of improved product design and functionality.